|

FRENSHAM MILL SUSTAINABILITY PROJECT |

|

Overall 'Carbon payback'

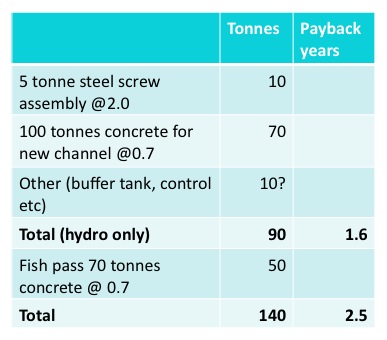

We became very conscious of the large quantities of carbon intensive concrete being used in both the new channel for the screw and in the specified design for the fish pass. We needed the reassurance that the scheme was not only financially viable but also made sense in relating the annual future carbon savings to the upfront carbon footprint of the scheme. The estimates below are very preliminary (constrained by lack of data on the carbon consumption of key components) But making provision for the key uses of concrete and steel seems to indicate a healthy 'carbon payback'

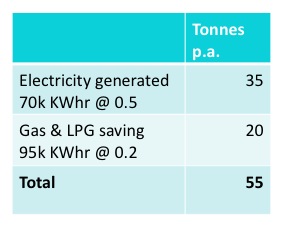

Annual savingsThe annual savings are estimated at over 50 tonnes per year of CO2, from 70k KWhr of renewable electricity generated and the saving of past gas and LPG consumption.

|

Cost/ paybackThe addition of the fish pass has added significantly to the carbon footprint of the scheme, but even allowing for this we believe that the project represents a decent 'carbon payback' of 2.5 years.

|